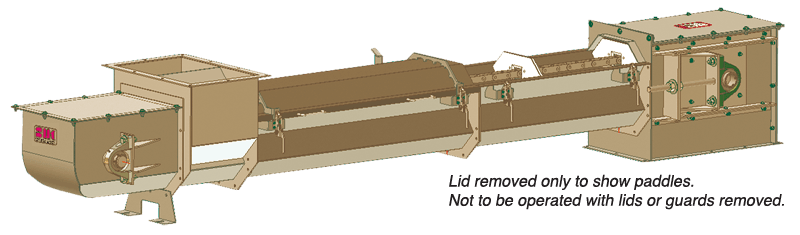

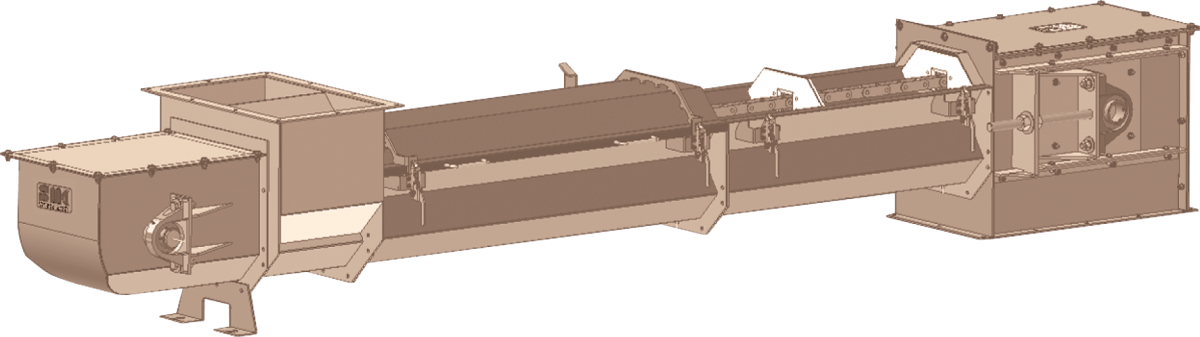

Side Wall Return™

THE SIDEWALL RETURN™ SURPASSES ALL OTHER DRAGS!

Your product is moved gently, completely and cleanly!

FEATURES:

- Bypass inlet allows product to bypass the return chain when entering conveyor.

- No transfer points to lose or leak product.

- Controlled de-watering available.

- Totally enclosed.

- CIP(clean in place) adaptable.

- Continuous flow from horizontal to incline.

- Full product discharge.

- Perfect for finished product

SIDE WALL RETURN MODELS & FEATURES

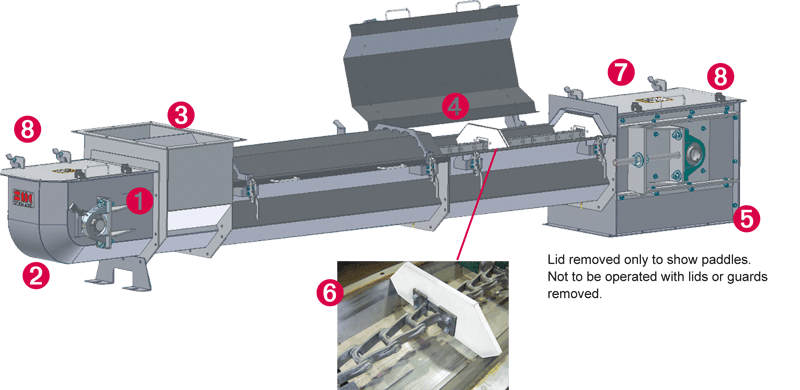

SWR - FG Features

HIGH YIELD PROCESSING DRAG CONVEYOR

Side Wall Return™ Drag Conveyor constructed for FOOD GRADE conveyance. Move product up to 200 feet with only two sprockets and four bearings.

- GENTLE HANDLING

- TOTAL PRODUCT RETENTION

- TOTAL PRODUCT DISCHARGE

- COMPLETELY ENCLOSED

FEATURES:

- Stainless steel bearings for shafts up to 2-1/2” diameter

- Fully contoured tail section

- Bypass inlets with Rigidized Metal deflector and side surfaces (Removable deflector for ease of cleaning)

- Return paddles travel above product for complete product retention and clean floors

- Head discharge with chain take up design

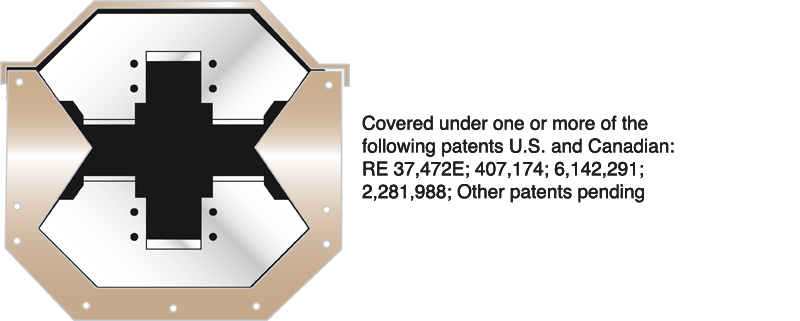

- Patented chain design

- White food grade UHMW paddles

- Hinged covers on head, tail, and trough sections (with

5’ max. cover length) for ease of access and

convenient sanitization

PRODUCTS AND INDUSTRY

Whole, sliced or diced fruits and vegetables, fresh and frozen. Click on,

Products We Move, to see a complete list.

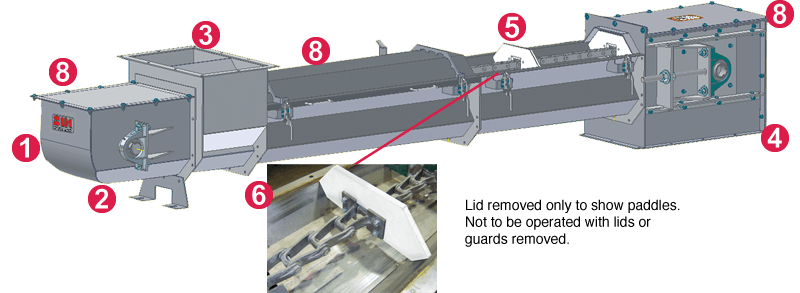

SWR - WS Features

HIGH YIELD DRAG PROCESSING CONVEYOR

Sidewall Return™ Drag Conveyor constructed for food waste management applications.

- Contained waste management

- Continuous conveying with no obstructions

SWR-WS Standard Features

- Standard tail design with outboard pillow block bearings and bolted cover

- Nickel plated housing with black oxide insert

- Low profile inlet

- Head with Take-up design, outboard pillow block bearings and bolted cover

- Return paddles travel above waste product for totally

enclosed waste management - Patented chain design

- White UHMW paddles

- Bolted lids

PRODUCTS AND INDUSTRY

All food processing waste – animal, mineral and vegetable. Click on,

Products We Move, to see a complete list.

SWR - LN Features

HIGH YIELD PROCESSING DRAG CONVEYOR

Sidewall Return™ Drag Conveyor constructed with a mild steel liner.

- Easy Liner Replacement

- Perfect Process

- Gentle Handling

- Fully Self Cleaning

SWR-LN Standard Features

- Self cleaning tail with outboard pillow block bearings

- Bypass inlet

- Low profile

- Head with take-up

- Full trough design with Side Wall Return™ paddle travel

- Product travel and return travel area

- Patented chain design

- UHMW paddles

PRODUCTS AND INDUSTRY

Abrasives • Minerals • Calcium Sulphate • Dicalcium Phosphate • Oyster Shells. Click on,

Products We Move, to see a complete list.

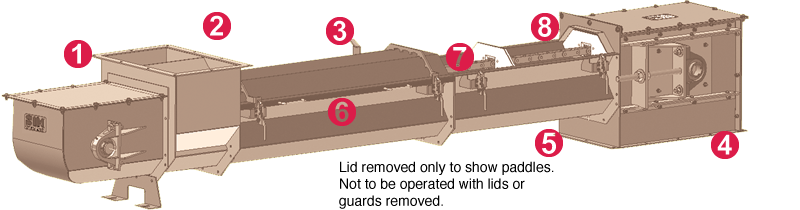

SWR - MS Features

HIGH YIELD PROCESSING DRAG CONVEYOR

Sidewall Return™ Drag Conveyor for non-food grade conveyance

- Perfect Process

- Gentle Handling

- Fully Self Cleaning

SWR-MS Standard Features

- Self cleaning tail with outboard pillow block bearings

- Bypass inlet

- Low profile inlet

- Head with take-up

- Full trough design with Side Wall Return™ paddle travel

- Product travel and return travel area

- Patented chain design

- UHMW paddles

PRODUCTS AND INDUSTRY

Grain • Wood by Products • Cellulose Fiber • Seed • Animal Feed • Pet Foods • Coffee Beans.. Click on,

Products We Move, to see a complete list.

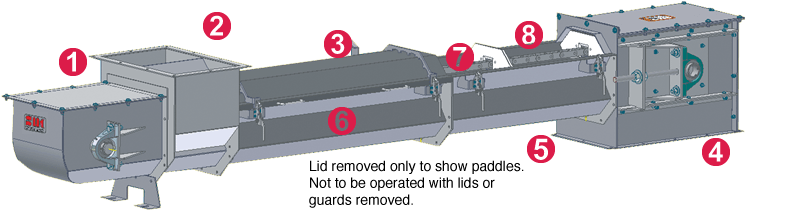

SWR - SS Features

HIGH YIELD PROCESSING DRAG CONVEYOR

Side Wall Return™ Drag Conveyor

- Perfect Process

- Gentle Handling

- Corrosive Resistant

- Fully Self Cleaning

Features:

- Self cleaning tail with outboard pillow block bearings

- Bypass inlet

- Low profile inlet

- Head with take-up

- Full trough design with Side Wall Return™ paddle travel

- Product travel and return travel area

- Patented chain design

- UHMW paddles

PRODUCTS AND INDUSTRY

Salt • Fertilizers • Corrosive Materials • Ice Cubes • Soft Water Softener Pellets • Hot Wood Pellets. Click on,

Products We Move, to see a complete list.

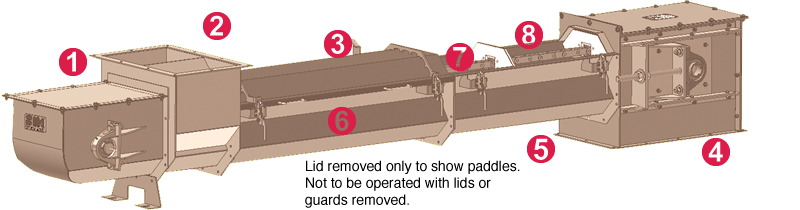

SWR - PF Features

HIGH YIELD PROCESSING DRAG CONVEYOR

Sidewall Return™ Drag Conveyor for food-grade or non-food grade conveyance

- Perfect Process

- Gentle Handling

- Fully Self Cleaning

SWR-PF Standard Features

- Self Cleaning Tail Design

- Bypass/Divided-flow inlet (used with finished product)

- Low profile inlet (used with fines and ingredients)

- Full trough design with Side Wall Return™ paddle travel

- Patented chain design

- UHMW Paddles (white, food-grade)

- Reversing capability (when specified)

- Bolted, Clamped or Hinged Covers

- Flush-mounted intermediate Dischargers

- Incline, Inverse & Horizontal Bend Sections

SWR Construction and Finish Options

- Available in Carbon and Stainless Steel

- SMC Smoke or White paint (custom color-match available)

- Weld Finish; standard weld finish on inside and outside

- Optional food grade internal welds (fully ground welds with no pits or crevices)

CAP - FG Features

HIGH YIELD PROCESSING DRAG CONVEYOR

On-Line Processing conveyance for food grade products.

- Aquatic processing

- Soaking

- Saturation

CAP-FG Capabilities

- Consistent product saturation

- Full product discharge

- Total de-watering capabilities

- Continuous flow on-line processing – horizontal to incline if desired

- Fully enclosed process results in higher yields, enhanced safety and improved sanitation

CAP-FG Typical Applications

- Product hydration

- Calcium chloride bath

- Water saving product receiving

CAP-FG Capacities

- Available in 2 sizes:

- CAP-24: Ideal for smaller capacity soaking processes

- CAP-48: Extra wide; up to 60,000 lbs./hr.

- Speeds and tonnage vary to achieve desired residence times

PRODUCTS AND INDUSTRY

Whole, sliced or diced fruits and vegetables.

CAP-FG Features:

- Gentle handling

- Total product retention

- Fully contoured tail section

- Bypass inlets with Rigidized Metal deflector and side surfaces (removable deflector for ease of cleaning)

- Return paddles travel above product for complete product retention and clean floors

- White food grade UHMW paddles

- Hinged covers on head, tail and trough sections (with 5’ max. cover length) for ease of access and convenient sanitization

- 1,900 - 24,000 FT3/HR

- Incline sections from 5° - 45° - continuous product flow from horizontal to incline

- Lengths from 10 feet to 200 feet

- Move product up to 200 feet with only two sprockets and four bearings

- Flush closing intermediate discharge gate eliminates product damage